Stop Termites & Rot! How the best LGSF manufacturer in West Bengal Protects Your Home from Humidity

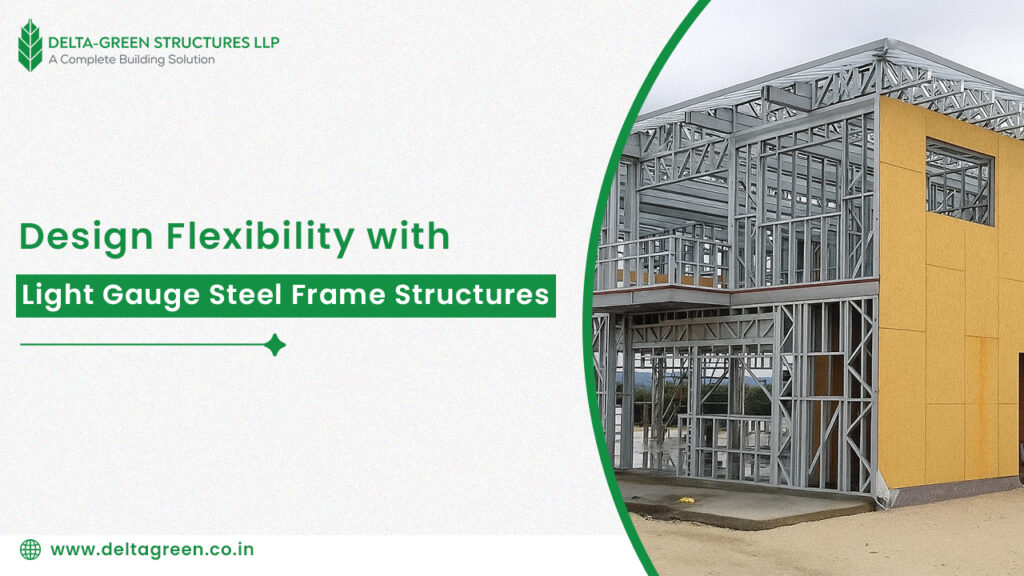

Your dream home in West Bengal represents security, comfort, and a legacy for generations. But lurking beneath the surface, the region’s relentless humidity, heavy monsoon rains, and warm climate create the perfect breeding ground for two of a homeowner’s worst nightmares: termites and rot. These silent destroyers can compromise structural integrity, damage priceless belongings, and lead to costly, invasive repairs. If you’re building or renovating, you need a solution engineered to defy these threats from the ground up. That solution lies with the best LGSF manufacturer in West Bengal, leveraging the inherent power of Light Gauge Steel Frame (LGSF) construction. This is where Delta Green Structure steps in, offering not just buildings, but impervious shields for your most valuable asset. Humidity, Termites, and Rot the relentless enemy in West Bengal West Bengal’s climate is defined by high humidity levels year-round, peaking during the monsoon season this makes construction complicated. This persistent moisture is the catalyst for decay : 1. Wood Rot Traditional building materials, especially wood, are highly susceptible. When moisture content in wood exceeds 20%, fungi thrive, feeding on the wood’s cellulose. This leads to: Dry Rot: Creates a cuboidal cracking pattern and spreads rapidly behind surfaces. Wet Rot: Causes wood to darken, soften, and lose strength, often localized to the wet area. Structural Weakening: Compromised beams, joists, studs, and flooring lead to sagging, cracking, and potential collapse. 2. Termite Infestations Subterranean termites are prolific across West Bengal. Thrive in Moisture: Damp soil and moist wood are their ideal habitats. Travel Silently: Build mud tubes to traverse foundations and reach wooden structures undetected. Devour from Within: Consume cellulose in wood, paper, and even certain fabrics, hollowing out structural elements and fixtures. 3. Mold and Mildew Beyond structural damage, high humidity fosters mold growth on walls, ceilings, and belongings, posing significant health risks (respiratory issues, allergies) and causing unpleasant odors and stains. Traditional brick-and-mortar or timber-frame homes constantly battle these elements, requiring vigilant maintenance, chemical treatments (which have their own environmental and health concerns), and often facing inevitable deterioration over time. Building a Fortress Against Moisture and Pests Light Gauge Steel Frame construction fundamentally changes the game. It replaces moisture-absorbent, cellulose-rich materials with cold-formed, high-tensile galvanized steel. This shift creates an inherently hostile environment for rot and termites: 1. The Power of Steel Non-Combustible & Non-Organic: Steel provides no food source for termites, fungi, or bacteria. They simply cannot consume it. Dimensionally Stable: Unlike wood, which swells, warps, and shrinks with moisture changes, steel maintains its shape and strength regardless of humidity levels. This stability prevents the cracks and gaps that allow moisture ingress and pest entry in traditional builds. Precision Engineering: Components are manufactured to exact tolerances in controlled factory conditions, ensuring tight fits and minimizing potential moisture pathways. 2. The Shield of Galvanization Corrosion Resistance: The secret weapon in LGSF is the zinc coating (galvanization) applied to the steel studs and tracks. This layer sacrificially protects the underlying steel from rust and corrosion, even in high-humidity environments like coastal West Bengal or areas with heavy rainfall. Long-Term Durability: High-quality galvanization (often G-90 or AZ-150 coatings) provides decades of protection, ensuring the structural skeleton remains sound and unaffected by moisture. 3. Integrated Moisture Management Systems Advanced Vapor Barriers: Strategically placed high-performance membranes prevent humid air from penetrating the wall cavities and condensing within the structure. Effective Drainage Planes: Systems like rainscreen claddings allow any incidental water that gets behind the exterior finish to drain away freely, keeping the structure dry. Optimal Insulation: Using non-absorbent insulation materials within the steel frame prevents moisture retention and maintains thermal efficiency. This is crucial, as wet insulation loses its R-value and can promote mold growth. By combining advanced vapor barriers, effective drainage systems, and moisture-resistant insulation, we ensure long-term structural integrity, energy efficiency, and a healthier indoor environment, protecting both the building and its occupants. The Comprehensive Benefits of Delta Green Structure’s LGSF Homes While defeating humidity, termites, and rot is paramount, choosing Delta Green Structure as your LGSF manufacturer in West Bengal delivers a cascade of additional advantages: Exceptional Strength and Durability: Steel frames withstand high winds, seismic activity, and heavy loads far better than traditional materials, offering superior safety and longevity. Speed of Construction: Factory prefabrication allows for significantly faster on-site assembly, reducing weather-related delays and getting you into your home sooner. Design Flexibility: LGSF enables complex architectural designs, vaulted ceilings, and large open spans without compromising structural integrity. Sustainability: Steel is highly recyclable, generates less construction waste, and our energy-efficient designs lead to lower operational carbon footprints. Reduced need for chemical termite treatments is another environmental plus. Fire Resistance: Steel is non-combustible, significantly enhancing fire safety compared to timber frames. Predictable Costs: Factory-controlled manufacturing minimizes material waste and reduces the risk of unforeseen delays and cost overruns common in traditional construction. Smooth Surfaces & Reduced Maintenance: LGSF walls provide incredibly straight and plumb surfaces for flawless finishes. Crucially, the elimination of wood in the structure drastically reduces long-term maintenance worries and costs associated with repainting warped wood, replacing rotten elements, or retreating for termites. With Delta Green Structure, you’re not just building — you’re investing in strength, speed, flexibility, and long-term peace of mind. Our LGSF solutions deliver unmatched performance today while protecting your investment for decades to come. Partner with the Best LGSF Manufacturer in West Bengal Don’t let West Bengal’s climate dictate the lifespan or safety of your dream home. Embrace the future of resilient, healthy, and durable construction. Choose a building system engineered from the start to defy humidity, repel termites, and eliminate rot. Delta Green Structure stands as West Bengal’s premier LGSF manufacturer and constructor, dedicated to delivering homes that are not just beautiful, but fundamentally stronger, safer, and designed to last. We combine cutting-edge LGSF technology with deep local expertise and an unwavering commitment to quality at every stage – from design and material selection to precision manufacturing and meticulous on-site assembly. Stop worrying about termites and rot. Start building a legacy of