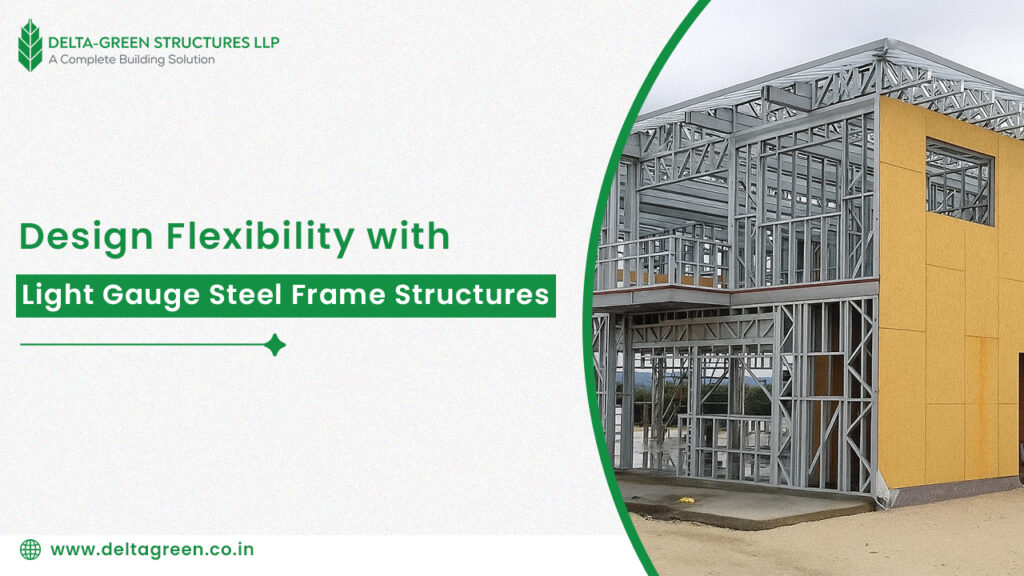

Design Flexibility with Light Gauge Steel Frame Structures

Forget the limitations of traditional bricks and mortar. If you’re envisioning a home, office, factory, or any building that breaks the mold, Light Gauge Steel Frame (LGSF) construction isn’t just an alternative – it’s a liberation for your design dreams. At Delta Green Structure, as a leading LGSF manufacturer in West Bengal, we have seen firsthand how this modern method empowers architects and homeowners alike to create truly unique, functional, and beautiful spaces. Let’s explore why LGSF is synonymous with unparalleled design flexibility. Breaking Free from the Rectangle: Why LGSF Excels Traditional load-bearing walls made of concrete or brick dictate a lot about a building’s form. They need to be thick, straight, and placed in specific locations to support the weight above. This often leads to boxy designs, limited spans, and challenges when trying to incorporate exciting architectural features. LGSF flips this script. Think of LGSF as building with a super-strong, incredibly precise skeleton. Walls, floors, and roofs are assembled using thin, cold-formed steel sections (studs, tracks, joists, rafters) manufactured to exacting standards. This steel framework carries the loads efficiently, freeing the walls from their primary structural role. This fundamental shift opens a world of possibilities: 1. The Magic of Open, Flowing Spaces: Say goodbye to cramped rooms and hello to vast, airy interiors. Long Spans: Steel joists and beams can span significantly greater distances than traditional wooden beams or reinforced concrete without needing intermediate supports like columns or thick walls. Imagine expansive living rooms, uninterrupted factory floors, or dramatic double-height atriums – all achievable with LGSF. Removable Partition Walls: Because internal walls in LGSF are often non-load-bearing (simply attached to the frame), they can be easily reconfigured, moved, or even removed entirely later on. Need to combine two offices into one large conference room? Or convert a large bedroom into two smaller ones as your family grows? LGSF makes renovations and future adaptations remarkably simple and less messy. Seamless Indoor-Outdoor Flow: Large sliding glass doors, bi-fold doors, or even entire glass walls can be incorporated effortlessly into the LGSF structure. The frame provides the necessary support around these large openings, allowing you to blur the lines between inside and outside, perfect for West Bengal’s beautiful landscapes and climate. 2. Curves, Angles, and Unique Shapes: Unleashing Creativity: Who says walls have to be straight? Curved Walls: LGSF components, while straight individually, can be assembled to create graceful curves, both internally and externally. This allows for stunning architectural features, unique room shapes, or simply softening the lines of a building for a more organic feel. Complex Geometries: Designing a building with unusual angles, cantilevers (sections projecting out without visible support), or intricate rooflines? LGSF’s precision engineering makes it possible. The steel sections can be cut and assembled to follow complex plans accurately, translating bold architectural visions into reality without the compromises often faced with traditional materials. Custom Facades: The external “skin” of an LGSF building (cladding, bricks, composite panels, etc.) is attached to the frame. This means you can achieve virtually any aesthetic – modern minimalist, traditional brickwork, contemporary mixed materials, or even replicating heritage styles – independent of the structural system underneath. The frame provides the strength; the cladding provides the style. 3. Effortless Multi-Story and Complex Roof Designs Building Upwards: LGSF is inherently strong and lightweight. This combination makes it exceptionally well-suited for multi-story buildings, including additions on top of existing structures (where weight is a critical factor). The precision of the system ensures floors are level and walls are plumb, simplifying construction. Roof Freedom: Dreaming of a dramatic vaulted ceiling, a unique gable, a complex hip roof, or even incorporating large skylights? LGSF rafters and trusses can be engineered and fabricated to create virtually any roof shape efficiently. The strength of steel allows for steeper pitches and larger overhangs than often possible with wood. Why This Flexibility Matters, Especially in West Bengal The design freedom offered by LGSF isn’t just about aesthetics; it delivers tangible benefits for building owners and occupants in our region: Optimizing for Climate: Design can prioritize features like cross-ventilation, strategic shading, and optimal window placement to combat West Bengal’s heat and humidity, enhancing comfort naturally and reducing long-term cooling costs. Maximizing Small Plots: On compact urban plots common in cities like Kolkata or Siliguri, the ability to build efficiently upwards or create clever, space-saving layouts without structural constraints is invaluable. Open plans make smaller spaces feel larger. Future-Proofing: Businesses evolve, families grow, and needs change. The inherent adaptability of LGSF (easy wall reconfiguration, potential for vertical additions) means buildings can evolve without costly and disruptive demolition and reconstruction. Speed to Occupancy: Faster construction times inherent to LGSF mean your uniquely designed space is ready for you to use or move into much sooner. Expressing Individuality: Whether it’s a modern villa in the suburbs, a state-of-the-art factory in an industrial zone, or a boutique store in a bustling town, LGSF allows your building to truly reflect your vision and brand identity without structural compromise. Delta Green Structure: Your Partner in Flexible Design As a premier LGSF manufacturer and construction specialist in West Bengal, Delta Green Structure isn’t just supplying materials; we’re enabling possibilities. We understand that every project is unique. Our role is to translate your architectural vision or functional requirements into a robust, efficient, and precisely engineered LGSF solution. Expert Engineering: Our team uses advanced software to model and calculate the exact structural requirements for even the most complex designs, ensuring safety and performance without stifling creativity. Precision Manufacturing: Our factory-controlled environment guarantees that every steel component is cut, punched, and formed to millimeter-perfect accuracy according to your specific design. This precision is fundamental to achieving complex shapes and ensuring smooth, fast on-site assembly. Local Expertise, Global Standards: Based in West Bengal, we understand local conditions, regulations, and architectural preferences. We combine this local knowledge with internationally recognized best practices in LGSF design and manufacturing. Embrace the Freedom of LGSF Construction Light Gauge Steel Frame construction is more than a building method;

Design Flexibility with Light Gauge Steel Frame Structures Read More »