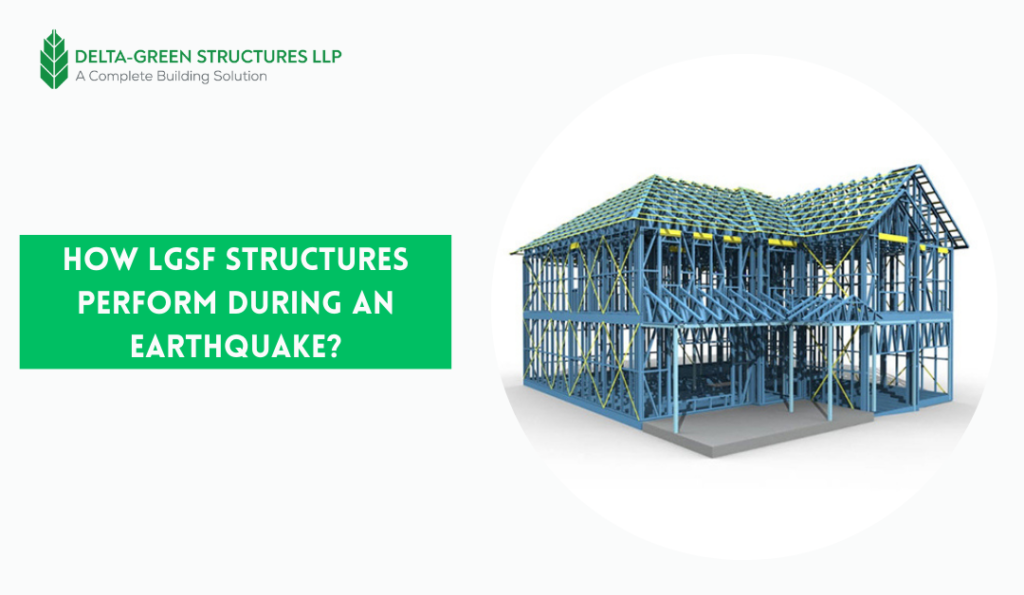

How Do LGSF Structures Perform During an Earthquake?

In areas prone to earthquakes, the materials and design of a building play a huge role in ensuring safety and resilience. Lightweight Gauge Steel Framing (LGSF) structures have become increasingly popular because of their many benefits, especially their excellent performance during earthquakes. Delta Green Structures, provides strong and affordable solutions to clients across India, ensuring safety and peace of mind. This article discusses how LGSF structures perform during earthquakes, their unique features, and why they are a dependable choice in earthquake-prone regions. What Are LGSF Structures? LGSF structures are made using cold-formed steel sections that are lightweight, strong, and flexible. They are widely used for homes, offices, and industrial purposes. These structures consist of thin steel sheets formed into profiles like studs and channels, creating a sturdy framework. Key features of LGSF structures include: Why Are Earthquakes a Concern for Buildings? Earthquakes generate strong seismic waves that create forces on buildings. These forces can: Traditional materials like brick and concrete often lack the flexibility needed to handle these forces, resulting in significant damage during strong earthquakes. How Do LGSF Structures Handle Earthquake Forces? LGSF structures perform exceptionally well in earthquake-prone areas due to their design and materials. Here’s how they resist seismic forces: 1. Lightweight Material:- LGSF structures are light, reducing the load on the foundation. This lower mass means less force acts on the building during an earthquake, lowering the risk of collapse, especially for taller buildings. 2. Ductility and Flexibility:- Steel, the main material in LGSF, can bend and deform without breaking. This allows the structure to absorb and disperse seismic energy, preventing sudden failure. 3. Engineered Design:- LGSF structures are designed with precision to meet seismic requirements. Advanced software ensures they comply with seismic codes. Bracing systems, like diagonal braces and shear walls, enhance resistance to lateral forces. 4. Uniform Load Distribution:- The interconnected steel frame spreads seismic forces evenly throughout the structure, reducing stress on specific areas and lowering the chance of localized failures. 5. Strong Foundation Connections:- LGSF structures are securely anchored to their foundations with advanced techniques. These connections are designed to withstand horizontal seismic forces, keeping the building stable. Real-Life Examples of LGSF in Earthquake Zones LGSF structures have shown outstanding performance in earthquake-prone areas worldwide: More Benefits of LGSF Structures Beyond earthquake resistance, LGSF structures offer many other advantages: Challenges and Solutions in LGSF Construction Though LGSF structures are highly effective, some challenges can arise: Delta Green Structures Key Features: LGSF structures have transformed construction in earthquake-prone areas with their lightweight, flexible, and durable design. These features make them a top choice for builders and homeowners looking for safety and resilience. As the risk of seismic activity remains high, LGSF technology offers a reliable way to protect lives and property. Delta Green Structures leads the way in LGSF technology, providing solutions that ensure safety and sustainability. Whether for homes or offices, LGSF structures deliver unmatched benefits, offering peace of mind in the face of natural disasters. To learn more about LGSF structures and their applications, contact Delta Green Structures today and take the first step toward a safer future.

How Do LGSF Structures Perform During an Earthquake? Read More »